About Us

HomeAbout Us

Our Company

The Nan Liu Group is a company based in Taiwan that is committed to the production of nonwoven goods that are of high quality and have a high value-added. Nan Liu Enterprise Co. Ltd. is working hard to expand its operations in developing markets such as Indto to satisfy the growing demand for products of superior quality in those regions.

India is the world’s second most populous country, which gives it a huge consumer market. In addition, it is one of the largest textile-producing countries and the world’s second most populous country overall. The scope of Nan Liu’s operations in India extends to a variety of spheres, such as the production of hygiene materials, surgical gowns, and high-end dust-free wiping cloths.

The years of experience and technological advantages in Taiwan as well as the advanced manufacturing facilities that Nan Liu has established in China have contributed to the company’s success in India. Customers in the Indian market have given Nan Liu’s products high praise and trust, and the company has been able to maintain a strong growth momentum despite the intense level of competition in the market.

Nan Liu is dedicated to delivering to its Indian clients the most cutting-edge and reliable goods and services possible by continuously innovating and upgrading its technological infrastructure. Nan Liu is confident that the company’s success in the Indian market will assist it in further expanding its global business and achieving even greater levels of success.

Mission &Vision

Our Chairman

Mr C.S. Huang, the Chairman of Nanliu Enterprise Co. Ltd. was born in Liujia Township, Tainan County, Taiwan.

Along with that, he is also the President of the Kaohsiung County Industrial Association, the Honorary President of the Taiwan Nonwovens Industrial Association, the President of the Asia Nonwovens Fabric Association (ANFA), President of Huang’s Genealogical Association of Taiwan, the Honorary doctorate of National Kaohsiung University of Applied Sciences, Honorary professor of Cheng Shiu University, and Honorary Professor at the Ling Tung University.

Our Chairman

Mr C.S. Huang, the Chairman of Nanliu Enterprise Co. Ltd. was born in Liujia Township, Tainan County, Taiwan.

Along with that, he is also the President of the Kaohsiung County Industrial Association, the Honorary President of the Taiwan Nonwovens Industrial Association, the President of the Asia Nonwovens Fabric Association (ANFA), President of Huang’s Genealogical Association of Taiwan, the Honorary doctorate of National Kaohsiung University of Applied Sciences, Honorary professor of Cheng Shiu University, and Honorary Professor at the Ling Tung University.

Our History

-

March : India Plant Started Production of Wet Wipes and Facial Sheet Mask.

-

March: India Plant started operation with Hot Air Through Line.

-

January: 300,000 masks for foreign aid arrived in Slovakia

-

March: Continental Pinghu Plant was awarded a sixth place among the top 30 taxpayers in 2019 by the Pinghu Economic Development Zone

April Obtained the factory registration certificate (medical equipment manufacturing, wholesale, retail) issued by the city government and the "manufacturing drug dealer licence" issued by the Health Bureau

April Obtained the brand name "Nanliu Medical Mask" from the Food and Drug Administration of the Ministry of Health and Welfare, and was included in the list of national mask teams. All medical masks were requisitioned.

October 2020 HBR Taiwan's Top 100 CEOs Ranked 56th in the Sixth South Enterprises -

January: Completion of the new Yanchao factory & celebration of the 40th anniversary.

January:Acquired ISO 45001: 2018 Occupational Health Management System

February:Qiaotou Head Office moved to the new Yanchao Factory

March: Start of production of the 2 new production lines in the new Yanchaoplant, Taiwan Cotton nonwoven line and 6.0-meter Spunlace fabric.

April:Start construction of Nanliu factory in India.

September Obtained - Supplier Ethical Information Exchange SEDEXCertificate (Suppliers Ethical Data Exchange, SEDEX)

November Obtained - Global Organic Textile Certification Standard GOTS certificate. The Global Organic Textile Standard, GOTS) -

March: Nanliu Pinghu plant expanded with #1-2 warehouses adding an extra 15,000 square metres of storage capacity. April: The 2017 annual industrial sales income and taxation of the Nanliu Pinghu plant indicate Nanliu is in the list of top 10 companies in the Pinghu Economic Development Zone. June: Soil levelling of Nanliu plant in Ahmedabad, Gujarat, India December: Annual consolidated revenue of 6.8 billion Taiwan dollars

-

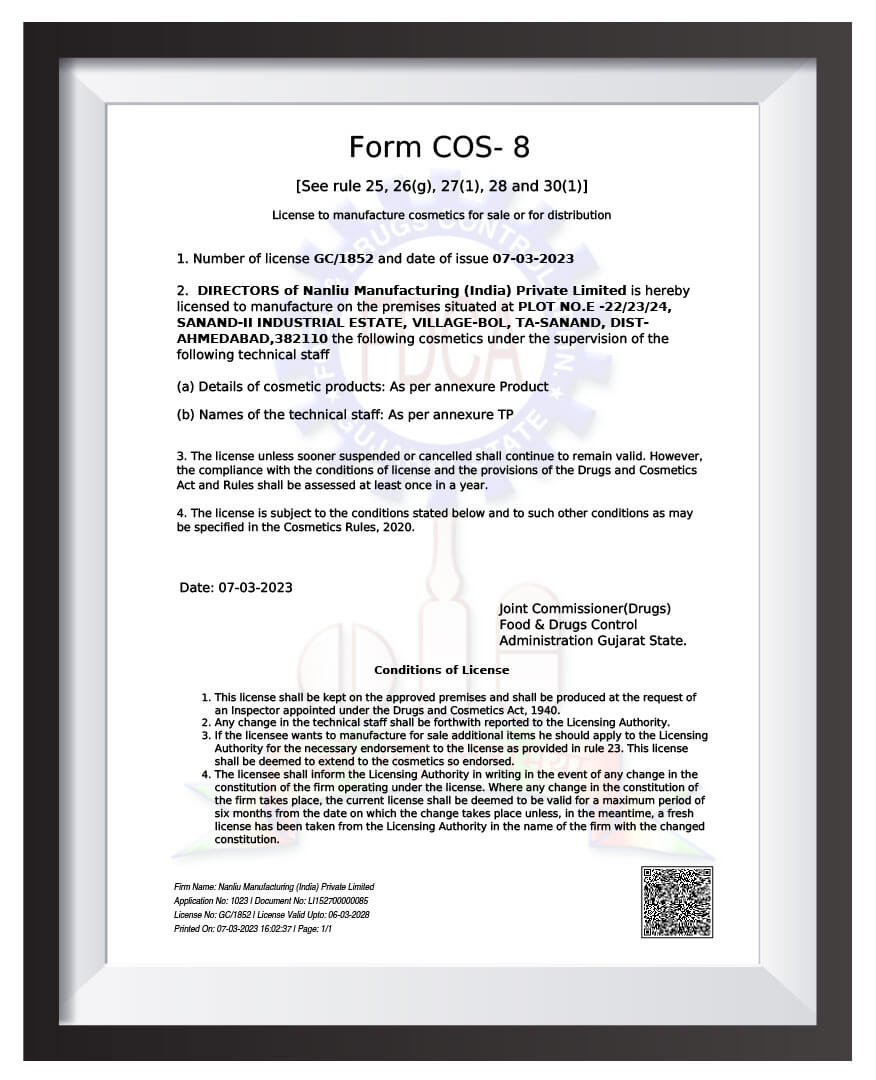

February: Start of construction of the new plant in Yanchao March: Won the ISO 9001 Quality Perpetual Award from the SGS International Certification Company. Passed the 2015 new edition certification of ISO 9001 as well as the 2015 new edition certification of ISO 14001. May: Per the regulations of the Ministry of Health and Welfare of the Executive Yuan, from 1st June 2017 "Baby Wipes for Special Use" were classified into the cosmetics management category. The Nanliu Ciaotou plant has been registered for approval in May (the first company in Taiwan to get the approval). September: Formal establishment of NANLIU MANUFACTURING (INDIA) PRIVATE LIMITED company in India. December: Nanliu won the "Model Innovation Award for Innovation and Management Quality," issued by SGS. Passed 2016 new edition certification of ISO 13485 2016.

-

March: Nan Liu (Ping Hu) was awarded the ninth position in industrial sales and the eleventh position in duty pay among all enterprises of the Pinghu Economic Development Zone for the year 2015. May: Attended IDEA 2016 Exhibition in Boston MA, USA September: Nan Liu was ranked 24 of the Top 40 world's largest non-woven companies (The Fourth position of Asia non-woven companies.) November: 2016 ANFA Nonwovens conference at Kaohsiung

-

Established Nanliu (Taiwan) Charities Foundation during Jan. Established Nanliu (Pinghu) Charities Foundation in January as the first foreign company in Pinghu to set up a Charities Foundation. Have installed two extra 3.8 M Thru-Air production lines and are in operation during Spring. Two new automatic facial mask processing lines are planned to be added for Taiwan and Pinghu plants in Q2, 2015 respectively. May: Awarded the Minister of Economic Affairs 3rd Taiwan Mittelstand from Premier Mr Mao Zhiguo Nan Liu was ranked 24 of the Top 40 world's largest non-woven companies (The 2nd position of Asia non-woven companies.)

-

Consolidated Sales Revenue has been up to NTD 5.33 billion. Have installed extra two facial mask processing lines for Taiwan and China plants respectively. Honoured the award of Technical Textiles merit and the 11th Outstanding Enterprise Manager of Southern Taiwan. Qualified as a candidate for the Excellent Performance Award by the Ministry of Economic Affairs.

-

Capital Increased by Cash to NTD 726 million. Consolidated Sales Revenue has increased to NTD 4.568 billion. Being Approved by Taiwan Stock Exchange for Initial Public Offering on May 7, 2013. The widest spunlace machine (6.2M width) has been installed and in operation since Q4, 2013 in the Pinghu plant. An extra automatic wet wipe converting line has been added to Taiwan & China plants respectively. Ranked 32 on the Top 40 companies List by Global Nonwovens Industry for 2013. The listed company was officially in Taiwan Stock Market on May 7, 2013. Adding additional wet wipes converting lines at both Taiwan and Ping Hu factories. Commissioning a new spunlace production line (width: 6.2M) in Quarter 3, 2013.

-

Capital Increased to NTD6.45 hundred million by Cash. Joint annual sales value up to NTD3.7 billion. FSC® Verification (License Code: FSCR C109346) ™-COC (Chain of Custody) certified ISO 13485 certified ISO 22716 Certified

-

Transfer profits into capital to the level of NT$ 600 million. Combined Annual Revenue of NT$ 3.52 billion. Obtain the certificate of ISO 9001:2008 on Quality Management Systems. Obtain the certificate of "Good Quality" from the governmental Dept. of Economics. On the procedure to apply for the certificate of ISO 13485 on Quality Management System for Medical Device & FSC™: COC on Good Management using Forest products. Add two automatic converting lines for cosmetic face masks, one 80-pcs wet wipes converting line, and one travelling packs wet wipes converting line.

-

Transfer profits into capital to the level of NT$ 528 million. Combined Annual Revenue of NT$ 2.86 billion. Obtained the certificate of ISO 14001:2004 on Environmental Management Systems. Medical fabrics for surgical gowns and drapes have been approved by major clients and received orders already. The Taiwanese plant applied for GMPC. Both the Taiwan and PingHu plants applied for ISO 14000. PingHu Plant: Second phase construction (post-process line) complete.

-

Transfer profits into capital to the level of NT$ 468 million. Combined Annual Revenue of NT$ 2.32 billion. Obtain the certificate of "Operational Headquarters in Taiwan" from the governmental Dept. of Economics. Medical Spunlace wood-pulp/PET fabrics have passed European EN 13795 & American I AAMI standards requirements. Combined Annual Profit of 2.32 billion New Taiwanese Dollars. Pinghu Plant High-Tech Wood-pulp Spunlace Fabrics passed European Standard- EN 13795 and AAMI. (Association of Advanced Medical Standard).

-

Combined Annual Profit of 1.9 billion New Taiwanese Dollars. Pinghu Plant obtained GMPC and ISO 2000 Quality Certifications.

-

The annual revenue has reached 1.69 billion. Surgical gown fabrics had received quality certification. The spun-lace production line of mainland China’s Pinghu Plant was under installation. Pinghu Plant had received the production permit for cosmetic & hygiene products. It would start production from the 2nd quarter of 2008.

-

Transfer profits into capital to the level of NT $ 423 million. Biotech care products occupied 30.6% of the total revenue. The annual revenue has reached NTD 1.53 billion. Surgical gown fabrics had developed successfully now and were in the process to receive the certification.

-

Transfer profits into capital to the level of NT $ 384.57 million. The 2nd spun lace product line was produced in the third quarter of the year. Biotech care products occupied 35.28% of the total revenue. The annual revenue has reached NTD 1.42 billion. Mainland China's Pinghu Plant began to build up.

-

Transfer profits into capital to the level of NT $349.569 million. Install the 2nd spunlace production line and it would produce in the third quarter of the year 2005 and it would contribute NTD 600 million into the annual revenue. Biotech care products occupied 28% of the total revenue. The annual revenue has reached NTD 1.3 billion.

-

Transfer profits into capital to the level of NT $ 326.7 million. Install a new 400 square metres clean-room quality workshop. Develop and manufacture cream & liquid cosmetics. The annual revenue reached NTD 1.16 billion.

-

Transfer profits into capital to the level of NT $ 297 million. Annual revenue exceeded NTD 1 billion, growing by 25%. Planned to purchase the second spunlace production line. Company stock was registered in Taiwan Secondary Stock Market on December 25.

-

Transfer profits into capital to the level of NT $ 275 million. The product order of spun lace fabrics in the Yanchao Plant exceeded the production capacity. Revenue grew up by 22%.

-

(Spunlace machine, wet wipes converting machine) had completed the installation and tests in September. It produces high-tech and high-quality spunlace nonwoven fabrics which are used widely in household wipes, soft wet tissues, paper pants, travelling towels, PU artificial leathers, etc. Capital increased to NT $ 250 million. The stock was offered publicly on July 7 of the year.

-

Another NTD 34.02 million was added to the capital and transferred profits into capital to have a capital of NTD 197.82 million. Build up the #2 facility, and purchased a spunlace line. Nanliu facilities have honoured the ISO9002 certification.

-

#3 thermal-bonded machine the line with Germany Thibau carding & Kuster high-speed thermal-bonded roller was tested successfully and produced well. The capital increased to NT $ 126 million this year.

-

The capital increased to NT $ 96 million and purchased the third thermal-bonded production line.

-

Purchased the #1 air-through machine with the carding machine from Germany "Hergeth" and the air-through machines from the Japanese Hirano Company, which was finished in March of the year. Then another hot melt machine was added in April.

-

Purchased #2 thermal-bonded machine with the carding machine from Germany Spinnbau Company and hot melt machine from Ramisch.

-

The capital increased to NT $ 66 million. In December of this year purchased a needle-punch machine from Dilo Company.

-

Purchased #1 thermal-bonded machine with the carding machine from Germany "Spinnbau" company and hot melt machine from Ramisch. Use Danish Danaklon fibres to produce hot-melt nonwovens to support diaper manufacturers from Taiwan and overseas.

-

The capital increased to NT $ 10 million. Added non-woven production lines and began an integral operation from fibres to finished products. The high-quality kitchen cleaning fabrics were to be sold to Japan by OHE in Hege county, Hainan Township in Japan. At the same time, the quality had passed the requirements on the 20th of the Japanese Food Sanitation Law. Purchased two high-performance nonwoven production lines and specialised in producing the lining cotton of bras to support Wacoal, Triumph of Taiwan and other manufacturers. The capital increased to NT $ 29 million.

-

The Nan Liu Enterprise Co. Ltd. combined with Nanliu Enterprise Agency at the site of 88 Bii Shiow Road, Chyau Tour Township, Kaohsiung County. Its capital was $6.6 million. At the same time, the production of grinding materials was developed successfully and owned 1200 square metres of the working area.

-

Established the company of Nanliu Enterprise Co. Ltd. on 166 Dingjing Road in Kaohsiung, producing and selling household cleaning fabrics. At that time, the capital was NT $1 million.